Die casting Industry

A substance that increases efficiency in forming aluminum and zinc parts using the die-casting process.

Welcome to the exciting world of the die casting industry, a dynamic and vital sector in today’s manufacturing landscape. Die casting is an efficient, cost-effective process that offers a broad range of shapes and components for various industries, including automotive, electronics, appliances, and more.

At the heart of this process are three crucial elements: diecasting lubricants, plunger lubricants, and aluminium flux. These elements play a pivotal role in ensuring the efficiency and quality of the finished products.

DIE CASING LUBRICANT

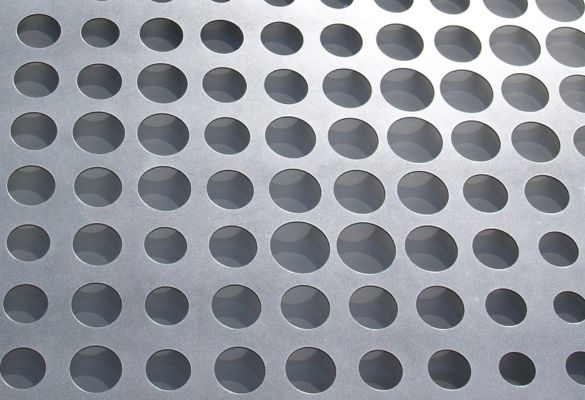

Diecasting lubricants are indispensable for facilitating the smooth release of castings from the die. They play a critical role in preserving the life of the die and ensuring a high-quality surface finish on the final product. Without them, the die could quickly deteriorate, resulting in loss of productivity and increased costs.

PLUNGER LUBRICANT

Plunger lubricants are equally important. They reduce friction and wear between the plunger tip and the shot sleeve during the injection of molten metal into the die. This extends the life of the components, reducing downtime for replacements, and ensures a more consistent, quality casting.

ALUMINIUM FLUX

Aluminium flux plays a vital role in the process as well. This chemical compound cleans, refines, and protects molten aluminium, ensuring the purity of the metal and preventing oxidation. This results in a superior final product with fewer defects and higher structural integrity.